SERVICES

Landform Design

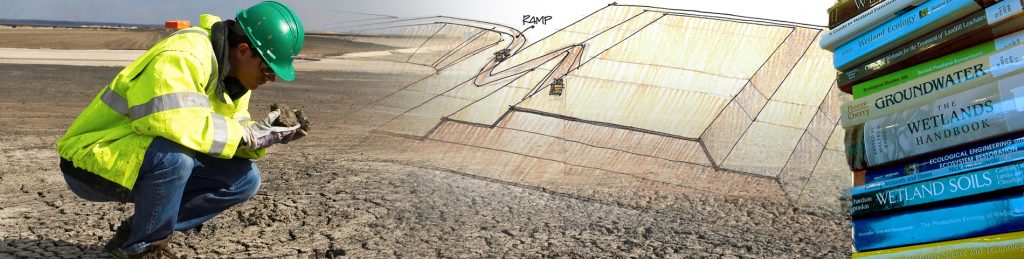

At McKenna Geotechnical, we appreciate the competing demands and unavoidable constraints facing landform design. Mine reclamation is about more than regrading and revegetating. Meeting corporate objectives and government regulations now requires an integrated design approach, ideally at the watershed scale, employing a multidisciplinary team, along with detailed schedules that span decades.

While most mine sites are destined to be used for recreation or conservation, others can be so difficult to restore that stability and a modest environmental impact are all that can be expected from reclamation. All are valid land uses, usually selected by the mine operator with input from stakeholders and regulators. We help navigate that process and guide the reclamation process to a successful conclusion.

In the late 1990s, Gord undertook research that laid the groundwork for much of what we now consider formal watershed design protocols. His approach has been embraced by Syncrude, Suncor, and Teck Coal, among other industry leaders. He is responsible for the investigation, design, construction, and reclamation of six commercial-scale watershed reclamation projects in Canada covering a total of 650 hectares. Another 2,000 ha are under construction, and closure at another four sites totaling 40,000 ha is under way using his designs.

McKenna Geotechnical embraces teamwork, which is essential to successful landform design. No one specialist can possibly embody all the expertise required. The range of knowledge required is vast, encompassing mine planning, geotechnical design, traditional knowledge, surface water, groundwater, soils, vegetation, and wildlife to name a few of the critical specialties. Founder Gord McKenna, over the past 30 years, has developed a working familiarity with a wealth of professionals who can satisfy all of these various requirements. Gord assembles the team and gets everyone working together toward the common goal.

Sample Projects

- Syncrude Mildred Lake Settling Basin East Toe Berm 1999 (182 ha)

- Syncrude SWSS Cell 32 2000 (39 ha)

- Syncrude S5 Dump 2001 (74 ha)

- Syncrude MLSB Coke Watershed 2001 (11 ha)

- Syncrude South Bison Hills Dump 2002 (100 ha)

- Syncrude S4 Dump/Gateway Hill 2004 (107 ha)

- Syncrude W1/W2 Dumps 2004 (seven watersheds covering 244 ha)

- Suncor MD2 Dump 2009 (34 ha)

- Syncrude Composite Tailings Prototype 2009 (80 ha)

- Suncor Pond 1 / Wapisiw Lookout 2010 (225 ha)

- Suncor Pond 5 and Pond 6 2011 (1168 ha)

- Suncor Nikanotee Fen and Watershed 2012 (35 ha)

- Syncrude East InPit / Sandhill Fen 2012 (52 ha).

- Faro Waste Rock Dump 2016 (350 ha)

- Faro Rose Creek Tailings Watershed 2016 (212 ha)

- Shell MRM External Tailings Facility 2016 (1420 ha)

Closure Planning

McKenna Geotechnical leads expert teams in developing mine closure plans at the landscape scale. Founder Gord McKenna has lead several breakthroughs in mine closure planning and relinquishment, including the use of formal goal-setting, design checklists, GIS tools, and assorted communication techniques. Some of Gord’s breakthrough innovations have become routine in oil sands closure planning, including approaches related to project design topographical surfaces, constraint maps, regional closure planning (for multiple mines) and landscape design risk assessments. The firm’s approach stresses the need to work with stakeholders, clearly define and obtain agreement on measurable goals, and work toward creating landforms that can be reclaimed reliably and efficiently. Stakeholder involvement, and consultation with First Nations, are increasingly critical elements to successful closure planning and implementation.

The long-term success of a mine depends on creating effective closure plans that are truly integrated with the long-range mine plan (ideally there is just one plan). The closure plans must be detailed enough to provide a solid basis for decision making by mine operations and mine development. They should provide a reliable basis for First Nations, regulatory agencies, and stakeholders to evaluate and provide guidance.

McKenna Geotechnical works with mines to ensure practical and realistic closure plans that are well communicated to all, and setting up the systems to help ensure they are followed and updated as needed. A well-done closure plan provides the ‘boundary conditions” for the more detailed design of the 6 to 24 landforms at each mine site, streamlining this process and improving the ultimate landscape performance and acceptance of the resulting mine reclamation.

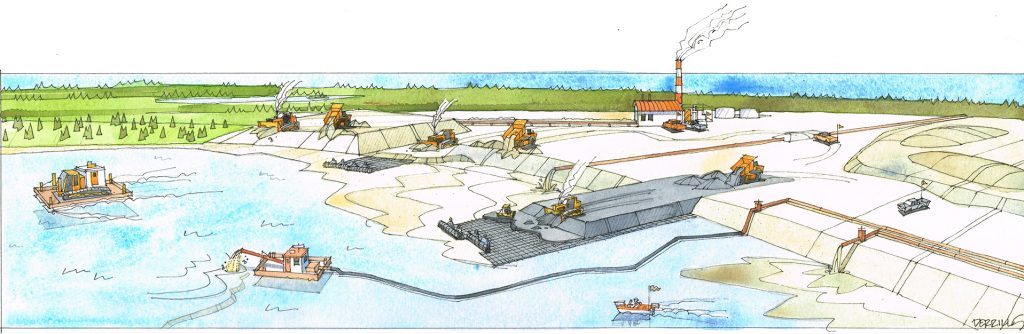

Soft tailings

McKenna Geotechnical recognizes that the permanent sequestering of tailings poses a significant challenge to responsible mine management. Soft tailings, defined as those which require special techniques for capping, trafficability, and reclamation, often catch mines by surprise. Soft tailings can prove difficult to stabilize, cover, cap and reclaim. Often the tailings require extensive processing to be cappable and reclaimable. Each mine presents unique features and opportunities for innovative solutions based on the best available science. Our decades of experience working on a variety of mines allows us to provide our clients with a broad suite of potential solutions from which to draw.

Founder Gord McKenna has been involved in oil sands tailings research and development for over 25 years, undertaking dozens of projects ranging from bench scale through piloting, prototyping, commercialization, operation, closure and reclamation. Example projects include commercialization of the Syncrude composite tailings, commercialization of soft tailings capping and trafficability testing methods, and new reclamation techniques. Most of this work happens in the field, dealing with real-life conditions in large pilots quickly moving on to commercial scale operations. While there are many soft tailings sites worldwide, soft tailings stabilization and reclamation projects are done as one-off projects and little published guidance exists.

Gord is well positioned to help companies benefit from decades of experience from individual mine sites on the range of reclamation solutions available to enhance both the environmental and economic performance of the mine. Our decades of experience working on a variety of mines allows us to provide our clients with a broad suite of potential solutions from which to draw. The costs of stabilizing and reclaiming soft tailings in particular can run to hundreds of millions of dollars — comparable to the cost of managing tailings during ore production. This reality makes sound tailings management a critical component of closure planning.

Gord has organized several soft tailings workshops over the past two decades:

Sample Workshops

- 1999: Soft tailings workshops in Edmonton Canada and at the WISMUT Uranium mine in Germany to share and benchmark international experience. Attended by about 120 participants from around the world.

- 2007: An oil sands soft tailings workshop at an oil sands mine to choose the main technologies for capping several tailings ponds that had reached full capacity. Two have since been stabilized and capped (about 7km2 in total).

- 2017: An oil sands industry capping workshop in Calgary to survey the international state of practice and the state of the art, with a focus on learning from industry experience in pilot, prototype, and commercial scale field activities.

Mining Technique

McKenna Geotechnical is intimately familiar with each phase of waste management and associated closure planning. Mines generate as much as 10 time more waste than ore, requiring the bulk of mine’s workforce to be tasked primarily with managing waste. It’s safe to say 90% of mine engineers and other specialists spend most of their time dealing with mine waste (overburden, tailings, and water). Dumps, dams, tailings ponds, and water management systems must be designed and monitored. Infrastructure to support waste management must be built. Closure plans must be drawn up. And stakeholders affecting by any of those aspects demand consultation; strong mines demand collaboration.

McKenna Geotechnical provides unmatched experience with oil sands geotechnical challenges, from pit walls stabilization and foundation integrity, to tailings research and development, closure planning, and reclamation. Exploitation of the oil sands has required the development of extraction techniques that challenged both the mining and petroleum industries. Those challenges continue to arise as attention turns to reclamation of mature mines. Building on muskeg foundations, designing spillways on weak slopes, constructing retaining walls in winter, and predicting aquifer pressure are just a few examples in a long list. We come to every project equipped with the knowledge and experience to apply lessons learned at other mines to the oil sands. The firm is also applying this expertise at coal and metal mines internationally.

Review Boards and Expert Panels

McKenna Geotechnical founder Gord McKenna has participated in several review panels, guiding operations, helping to ensure dam safety, and adopting landform design for large dams and dumps. He also provides advice on research and development programs. Belonging to such panels has given Gord a chance to collaborate with experts from many other disciplines.

Sample Boards and Panels

- CEMA Landform Design Checklist 2003-2004

- Questa Rockpile Weathering ADTI Panel 2006-2009

- Albian InPit Dyke Design and Construction Internal BGC team 2008-2012

- Suncor Pond 5 Coke capping review team 2008-2010

- CEMA End Pit Lake Guidance Document 2010-2012

- CTMC Oil Sands Tailings Roadmap 2010-2012

- Strategic Advisory Panel on Selenium Management 2010-2011

- MEND Cold Regions Cover System Design Technical Guidance Document 2011-2012

- University of Alberta Land Reclamation International Graduate School Management Board 2012-2016

- CEMA Guidelines for Wetlands Establishment on Reclaimed Oil Sands Leases 2012-2014

- De-Licensing of Oil Sands Tailings Dams: Technical Guidance Document 2012-2014

- Syncrude Base Mine Lake R&D Review Panel 2012-2014

- Syncrude EIP Landform Design Review Team 2012-2014

- Canadian Natural Albian Tailings Geotechnical Advisory Panel 2013-present

- Council of Canadian Academies Expert Panel on the Potential for New and Emerging Technologies to Reduce the Environmental Impacts of Oil Sands Development 2013-2015

- INAP Cover Systems Guidance Document 2014-2017

- CanAus Water Management Advisory Team 2015-2016

Teaching

As adjunct professor at the University of Alberta’s Department of Renewable Resources, Gord McKenna has the honour and privilege of helping shape the next generation of geotechnical engineers. He also lectures each year at the University of British Columbia and the B.C. Institute of Technology and offers short courses to corporations, organizations and educational institutions on request. Gord has had the opportunity to teach undergraduates, graduate students, professors, practitioners, regulators, stakeholders, and members of First Nations communities. The unifying theme in his lectures is the fostering of an appreciation for design strategies that meet the needs of both society and industry.

Over his three decades in the business, Gord has come to value the benefits of mentorships, and has overseen the early careers of dozens of young engineers as they begin their career. All members of the McKenna Geotechnical team are encouraged to develop such relationships as part of their responsibility to an industry with an ever-evolving scientific foundation. Gord publishes regularly in conferences and journals. A list of his publications over the last 30 years is available here.

Sample Courses

- Successful Reclamation – CIM Calgary ’99 – Calgary 1999

- Landform design checklist – CEMA – Fort McMurray 2003

- Geostatistics for hydraulic conductivity – Syncrude Canada – Fort McMurray 2004

- Landform design for oil sands tailings – Canadian Geotechnical Society – Calgary 2006

- Landform design – Tailings and Mine Waste ’08 – Vail 2008

- Oil sands geotechnique – BGC Engineering – Vancouver 2008

- Landform design – Tailings and Mine Waste ’09 – Banff 2009

- Landform design for oil sands – Syncrude Canada – Fort McMurray 2010

- Oil sands geotechnique – BGC Engineering – Vancouver 2010

- Landform design – Tailings and Mine Waste ’11 – Vancouver 2011

- Landform design – BGC Engineering – Vancouver 2012

- Oil sands geotechnique – BGC Engineering – Kamloops 2012

- Landform design – ICARD 2012 – Ottawa 2012

- Sustainable Mining Now – Mine Closure ’12 – Brisbane 2012

- Landform design and closure planning – University of Alberta Mining Engineering – Edmonton 2013

- Landform design – University of Alberta, LRIGS – Edmonton 2013

- Landform design and covers – CLRA ’13 – Whitehorse 2013

- Landform design and cover – Tailings and Mine Waste ’13 – Banff 2013

- Landform design for oil sands – oil sands company client course – Calgary 2013

- Landform design for oil sands – oil sands company client course – Calgary 2013

- Mine closure seminar – BGC Engineering – Santiago 2013

- Oil sands geotechnique – BGC Engineering – Vancouver 2014

- Landform design and closure planning – University of Alberta Mining Engineering – Edmonton 2014

- Landform design and covers – Seminar on Cold Regions- Cover Systems and Mine Closure – Whistler 2014

- Landform design for oil sands – oil sands company client course – Calgary 2014

- Hot Topics in oil sands tailings management – International Oil Sands Tailings Conference – Lake Louise 2014

- Landform design and closure planning – University of Alberta Mining Engineering – Edmonton 2015

- Landform design and reclamation for northern mines — Northern Latitudes Mining Reclamation Workshop – Juneau 2015

- Landform design for oil sands – oil sands company client course – Calgary 2016

- Landform design and closure planning – University of Alberta Mining Engineering – Edmonton 2016

- Restoring land after the oil sands – meeting Community needs – Fort McMurray NO. 468 First Nation – Anzac 2017

- Soft Tailings Capping Workshop — oil sands company client – Calgary 2017

- Introduction to Closure Planning and Landform Design – University of Alberta Mining Engineering – Edmonton 2018

- Landform Design Short Course – gold mine client – Northern Ontario 2018